MenuClosed

Scan on the official WeChat platform

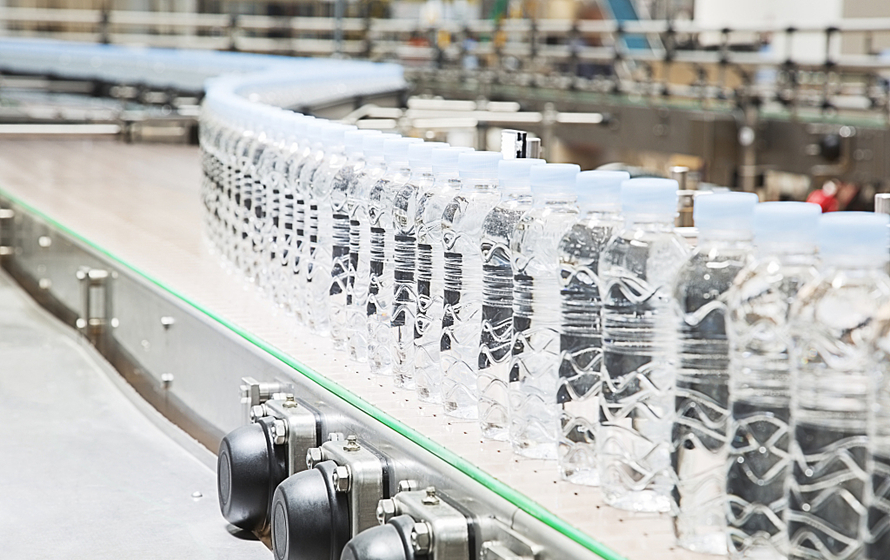

Filling machines are widespread in many industries, including solids handling, chemical, food, beverage and pharmaceutical, often operating continuously around the clock. Industrial sensors detect containers, lids, labels and caps, measure fill levels and more, and play a vital role in keeping automated filling equipment running reliably, accurately and with minimal downtime.

Customer Demands:

In a bottling plant, filled bottles are capped and then shrink-wrapped together to produce rigid packs of bottles. A missing cap or bottle is a serious quality fault that must be eliminated reliably.

Application:

A sensing solution is required to ensure that all bottles undergo an individual check to confirm they have been capped. This check takes place immediately before the bottles join the packaging line. Once this quality check has been successfully completed, the bottles will be packed together in specified quantities prior to dispatch. The materials involved in this task make it particularly suitable for capacitive sensing.

Solution:

HC-P30 series capacitive sensors have been selected for this application. They have an industrial-grade POM housing that meets protection class IP 67, which guarantees that these sensors will easily withstand regular cleaning work carried out on the machine. The operating distance can be adjusted directly on the sensors by means of a 20-turn potentiometer.

A single sensor is mounted over the bottle conveyor, forming a gate through which each bottle passes. The HC-P30 series checks for the presence of bottle caps by identifying changes in permittivity. If the sensor detects a bottle neck without a cap, the permittivity will be different from the preset value. Any reject bottle is immediately detected and removed from the line. The sensor also serves to count bottles passing the packaging process to ensure correct pack numbers.

Customer Values:

Reliable detection of reject packs

Reliable confirmation of pack quantities

Cost effective solution

Simple process and quality control

Specific Product Advantages:

Easy adjustment directly on sensor

Robust construction with IP67 protection

Proven reliability

High switching accuracy

Scan on the public